Cutting 40″ Collet with Houston Metal Sawing

Today we’re going to visit Houston Metal Sawing, one of Houston’s premier cutting facilities.

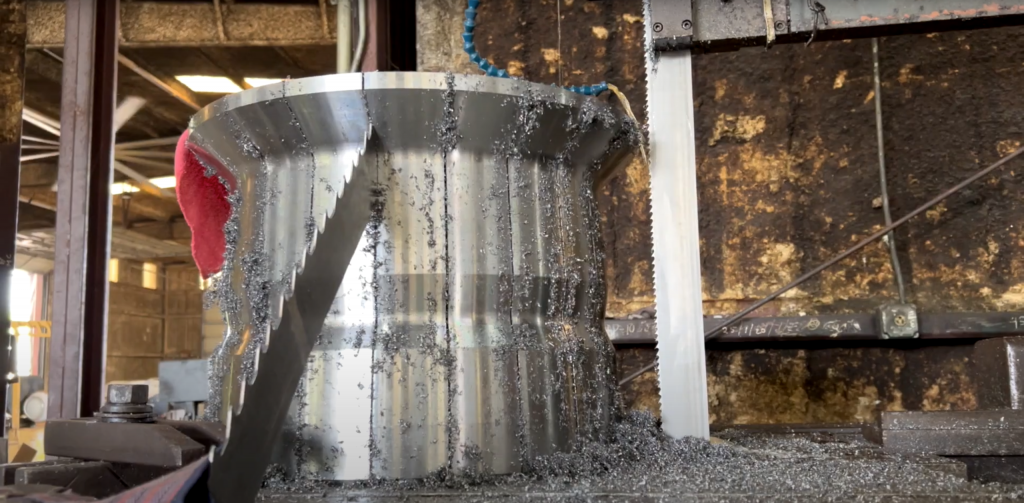

They’re working on collet connectors, Austin is gonna show us what they use to cut collet from various sizes.

Table of Contents

What Are Collet Connectors?

Collet connectors are very common in the oil and gas industry, they withstand the bending stresses and separating forces caused by well pressure, riser tension, and vessel motion. The one they’re working on today is made out of 4130 Chromoly, ensuring a greater resistance to corrosion and oxidation.

The QSaw Q601

For this kind of application, they use our QSaw Q601 M42 Bi-Metal blade, ideal for cutting hard steels or in high production applications and can be used on all types of band saws.

They’re pairing this blade with the HEM V200, a vertical heavy-duty bandsaw known for its high performance and versatility, running it at around 190 feet / minute.

Using Coolant

We also recommend using coolant for this type of application, here we can see them using the QFluids C-5200 Semi Synthetic Coolant, perfect for lubricating and cooling the band saw blade.

If you liked this video, click here to get in touch with Houston Metal Sawing or log on to sawblade.com to discover our wide range of sawing products!