In the world of precision metal cutting, selecting the right tools for challenging materials is crucial. Nickel and exotic-based alloys, known for their resilience and hardness, require a tool that’s exceptionally efficient. The Q© 701 SP, M71 Superior Performance Band Saw Blade stands out as a significant solution in metal fabrication.

Key Features of the Q701 Superior Performance M71 Blade

The Engineering Behind the Blade

This blade is not just a cutting tool; it’s an advanced engineering solution designed for the toughest materials.

Features That Make a Difference

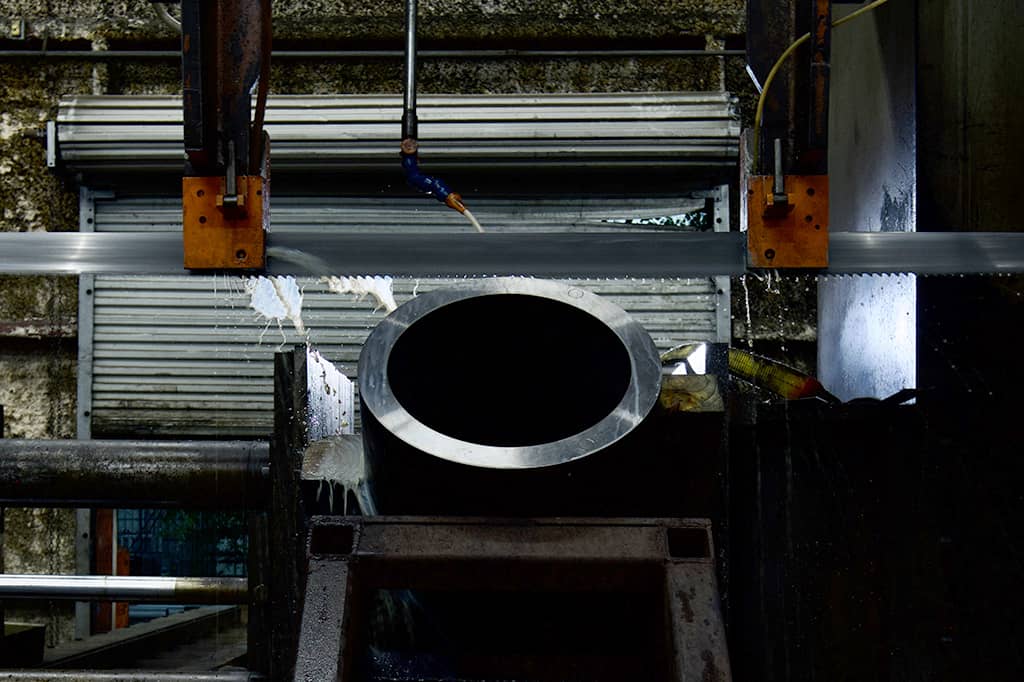

- Ground M71 Tooth Variable Height: Adapts to varying cutting requirements, ensuring precision.

- Fast Cutting with Pulsating Action: Increases the cutting speed, especially on hard metals.

- Hardness of HRC70: Ensures durability and resistance to wear.

The Benefits of Using the Q© 701 SP, M71 Bandsaw Blade

Advanced Performance

- Fast Cutting on Difficult Steels: Its design allows for quicker cuts without sacrificing quality.

- Lower Cost Per Cut: More efficient than other blades, reducing overall operational expenses.

- Versatility Across Machines: Compatible with a variety of sawing machines.

Applications of the Q© 701 SP, M71

The Q701 M71 bandsaw blade excels in its versatility and capability to handle materials like:

- Nickel and exotic-based alloys such as Inconel, Titanium, and Hastelloy.

- Work hardening steels and nickel-base superalloys.

- Other materials including Stainless Steel, D2, and Monel.

The Science of Cutting Tough Alloys

Specialized Tooth Geometry for Hard Materials

Creating a blade that not only cuts but excels in slicing through nickel and exotic-based alloys requires an innovative approach. The Q701 SP, M71 blade uses specialized tooth geometry, complemented by ground 8% Cobalt high-speed steel tooth tips, offering superior performance.

Improved Chrome Backing

Durability is key when cutting through tough materials. The robust chrome backing of the Q701 SP, M71 blade ensures longevity and aids in resisting heat and wear, making it a durable solution for heavy-duty cutting tasks.

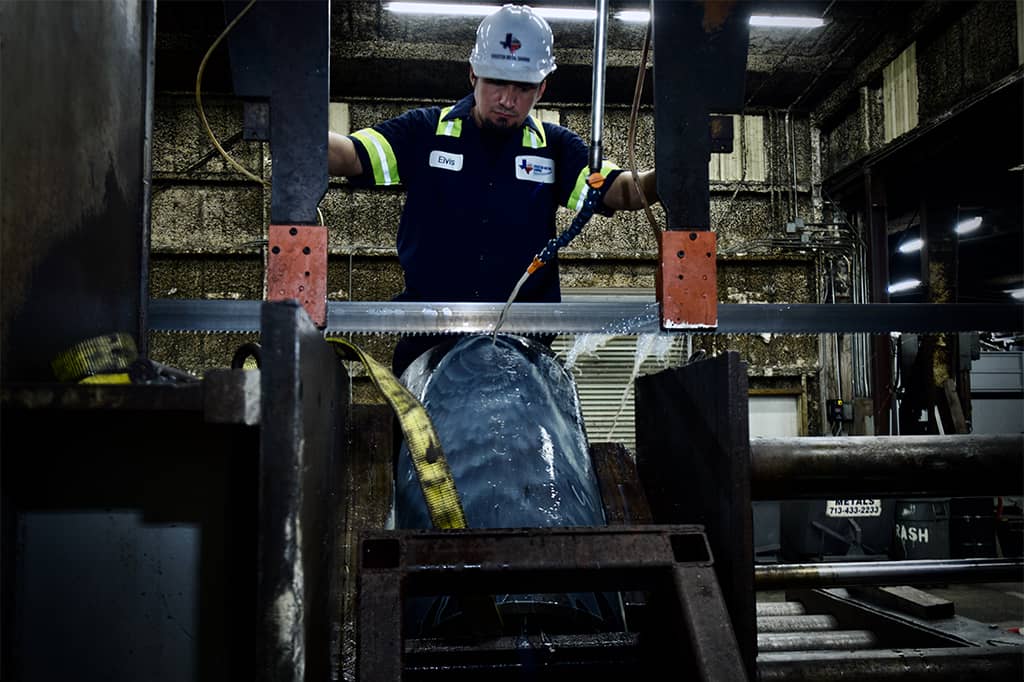

Insights from Real-World Users

Bridging Durability and Efficiency

As highlighted in this video featuring Austin from Sawblade.com and Daniel, General Manager at Houston Metal Cutting, the Q© 701 SP, M71 bandsaw blade has made significant strides in the industry. Its capability to cut through a variety of materials without frequent blade changes has made it a top choice for both structural carbon steel and hard alloy steels.

5 Essential Tips for Maximizing the Q701 Bandsaw Blade Performance

- Proper Installation: Ensure correct installation and tensioning for optimal performance.

- Regular Maintenance: Clean and check the blade regularly for wear to extend its life.

- Appropriate Feed Rate: Adjust the feed rate based on the material for efficient and smooth cuts.

- Use of Coolant: Apply suitable coolants to enhance cutting performance and prevent overheating.

- Careful Storage and Handling: Store the blade properly when not in use to prevent damage and ensure safety.

Conclusion

The Q© 701 SP, M71 Superior Performance Band Saw Blade represents an advance in technology for cutting hard, work-hardening steels and nickel-base superalloys. Its unique design, coupled with its ability to deliver fast, efficient cuts while reducing costs, makes it an essential tool in the metalworking industry.

Experience the cutting-edge difference with the Q701 SP, M71 bandsaw blade, distributed by Sawblade.com – where advanced engineering meets efficiency in metal cutting.