Selecting the appropriate sawing fluid is not just about improving your cutting process; it’s about enhancing blade longevity, promoting workplace safety, and ensuring environmental responsibility. Understanding the options and their benefits is crucial to the success of your project.

Why Use Coolants in Sawing Operations?

Coolants are not just an addition; they’re a necessity for several reasons:

- Temperature Control: They prevent overheating by cooling both the blade and the material being cut.

- Lubrication: Proper lubrication ensures smooth cutting operations.

- Cleanliness: Coolants help clear chips and debris from the machine, ensuring it remains in optimal working condition.

Understanding Your Choices

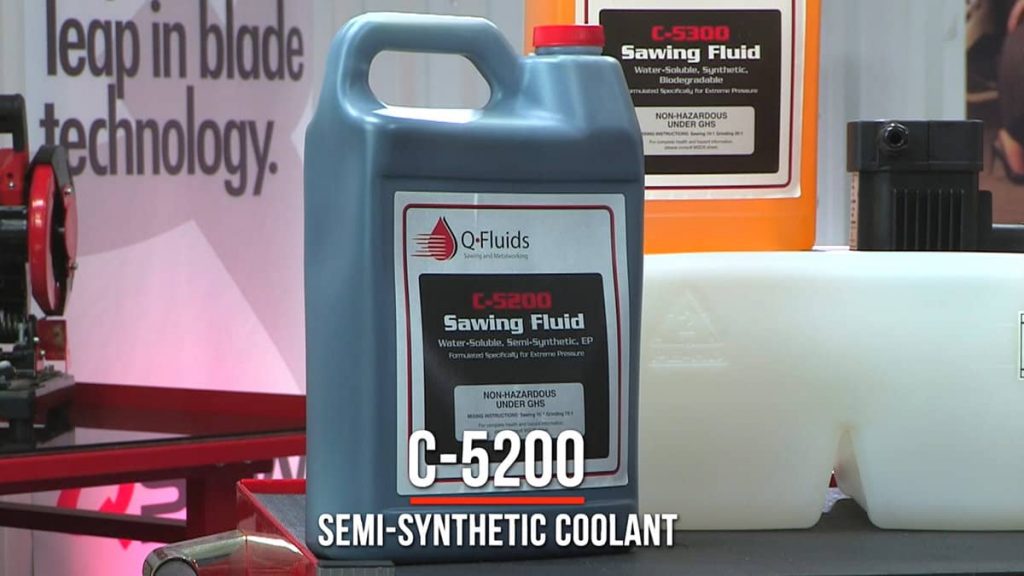

C-5200 Semi-Synthetic Coolant

Ideal for applications with both ferrous and non-ferrous metals, the C-5200 is designed to prolong blade life while reducing wear on your machine. With water-soluble properties, this coolant significantly diminishes frictional heat, thus enhancing cutting performance.

C-5300 Full Synthetic Coolant

Prioritize environmental consciousness with the C-5300. Apart from being biodegradable, it lacks harmful chemicals. This fluid is especially recommended when working with hard water. Notably, it’s a top choice for fabrications and welding operations as it doesn’t leave behind any oily residue.

C-5500 Mist Lubrication Fluid

For those seeking a neater cutting experience, the C-5500 system might be the answer. Using a combination of air and coolant, this method delivers a saturated mist right at the blade before the cut initiates. Apart from being eco-friendly, this system is also based on MQL (Minimum Quantity Lubricant) technology, ensuring minimal wastage and a cleaner working area.

Making the Right Decision

When selecting a coolant, always revisit your cutting goals.

- If your work involves cutting heavy solid materials, the lubricating properties of the C-5200 will be highly beneficial.

- If environmental friendliness, long tank life, and no residue are on your checklist, consider the C-5300.

- Lastly, if you’re after superior lubrication and a clean work environment, the C-5500 mist coolant, with its minimal residue, is the way to go.

Five Tips for Sawing Fluid Selection

- Understand Your Needs: Consider the material you’re cutting and the desired finish.

- Prioritize Safety: Ensure the fluid doesn’t contain harmful chemicals.

- Think Environmentally: Lean towards biodegradable or eco-friendly options when possible.

- Consider Maintenance: Some fluids might require frequent changes, while others last longer.

- Evaluate Costs: Factor in not just the upfront cost of the fluid but also the potential savings in terms of blade longevity and reduced machine wear.

Visit Sawblade.com to find the perfect sawing fluid tailored to your needs. Always remember to make informed decisions, not just for efficiency but for the environment and your safety.