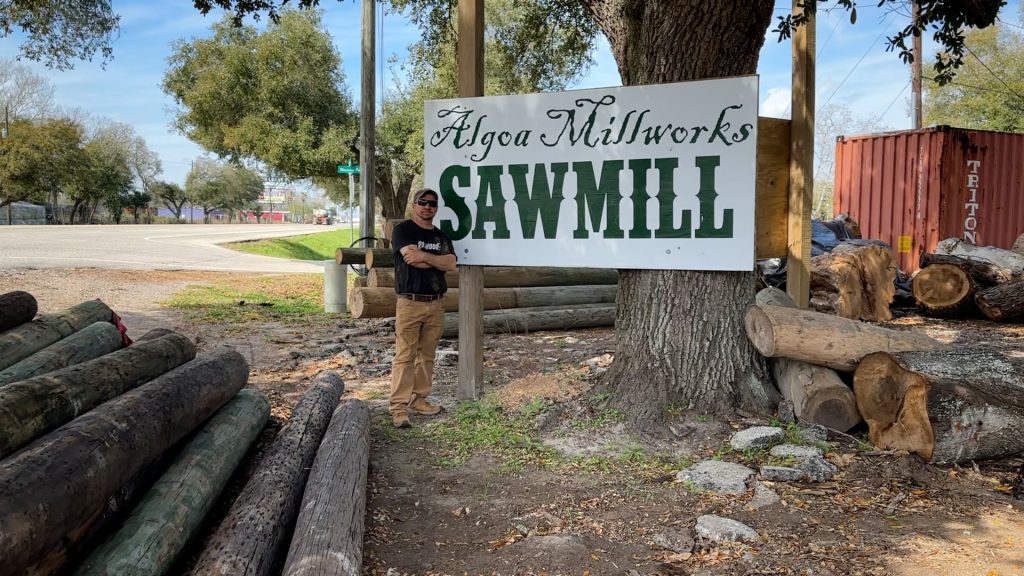

For Cory Pullen, what started as a simple hobby working on furniture has grown into Algoa Mill Works, a place where local wood is turned into all sorts of custom pieces. Based in Houston, Texas, Cory has been running the business for eight years now, and during a recent chat with the folks from Sawblade.com, he shared his story and a bit about how he works with wood. If you’re into woodworking, or just love seeing local wood turned into something special, stick around—we’ve got a story for you.

From a Weekend Hobby to a Full-Time Business

Cory’s story starts like many do, with a hobby he loved. “I’ve been at this for eight years, just started out working on furniture for fun,” Cory explains. “Then folks started coming by, asking to buy the wood, and I figured we might have something here.”

That’s when Cory got serious about his woodworking and bought his first sawmill. Fast forward, and now Algoa Mill Works is home to five sawmills, including a big Baker 36-65D that can handle logs up to 24 feet long. Cory and his team use it to make custom beams for homes and businesses, especially the big ones you just can’t find in most places.

The Right Tools Make a Difference

When you’re working with wood like Cory does, the tools you use are key. One of the big game changers in his shop is the Q910 carbide blade from Sawblade.com. “That Q910 blade really makes a difference for us,” Cory says. “It cuts through everything we throw at it, whether it’s hardwood or softwood, and it gives us a smooth, clean cut.”

With the help of the Q910 carbide blade, Cory can cut everything from large beams to custom tables with precision, turning local logs into beautiful furniture.

Making Something Out of Local Trees

Algoa Mill Works is all about using local wood to create custom pieces. “Most of the wood we work with comes from right here in the area,” Cory shares. “A lot of folks don’t realize that the dead tree in their yard could be turned into something real nice.”

Cory has made everything from small lamp tables to massive 13-foot black walnut conference tables, giving each project the care and attention it needs. “We just finished a big table that was 13 feet long and about 4 and a half feet wide. The customer told us what color, thickness, and finish they wanted, and we made it happen,” he says.

Kiln Drying for the Long Haul

Once the wood is cut, Cory makes sure it’s ready to last. He kiln-dries all the wood at Algoa Mill Works to make sure it’s strong and ready for whatever project it’ll be used for. “After we cut it, we load it into the kiln, cook it at about 130° for four weeks, then pull it out and run it through the planer,” Cory explains. The result? Wood that’s solid and ready to be made into custom pieces, whether it’s a dining table or beams for your house.

What’s Next for Algoa Mill Works?

For Cory and his team, the goal is to keep doing what they love—working with local wood to create custom pieces that folks can enjoy for years to come. With five sawmills, including a smaller Woodland Mills setup for working on smaller logs, and the reliable Qsaw 910 carbide bandsaw blade for precision cutting, Algoa Mill Works is ready for whatever projects come their way.

If you’re ever in Houston, stop by Algoa Mill Works and see what they’re working on. You might just find the perfect piece for your home, or at least get some inspiration for your next woodworking project.